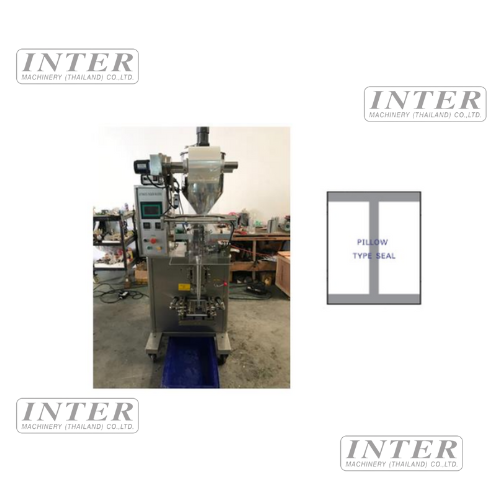

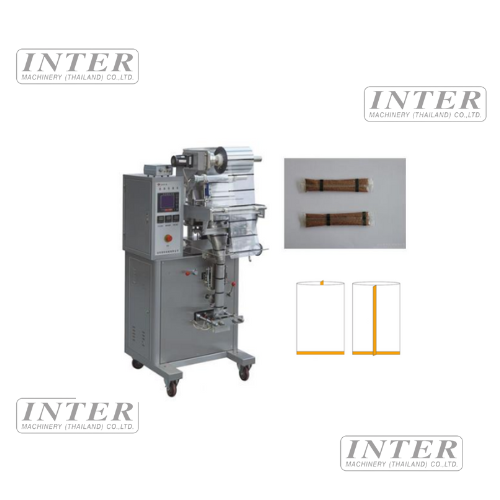

เครื่องบรรจุภัณฑ์แนวตั้ง

รหัสสินค้า: SLJF-4J20KG

เครื่องบรรจุแนวตั้ง รุ่น SLJF-4J20KG

Technical Parameter

| Type | SLJF-2J15KG | SLJF-4J25KG |

|---|---|---|

| Power voltage | 380V 50HZ | 380V 50HZ |

| Install request | 380V | |

| Inverter brand | TAIDA | TAI DA |

| Total power | 13.5KW | 21KW |

| Motor power | 11KW | 15KW |

| Motor speed | 2500R/MIN | 2500R/MIN |

| Side motor power | 1.5kw*1 | 1.5kw*3 |

| Side motor speed | 2500 | 2500 |

| Open cover | MA40*250 | MA40*250 |

| Powder Out | SC50*250 | SC50*250 |

| Barrel size | 45cm(d)*23cm(h) | 55cm(d)*55cm(h) |

| Material | (SUS304) | (SUS304) |

| Capacity | 5-15kg | 10-25kg/桶 |

| Dimension (L*W*H) | 1550*1150*1300MM | 1730*1520*1400MM |

| Weight | 450kg | 500kg |

รายละเอียดสินค้า

1. This machine is suitable for use in the cosmetics, pharmaceutical, food, chemical, and dye industries.

2. It features two mixing motors that operate from different angles—one from the bottom and one from the side of the mixing barrel. These motors perform crushing, shearing, and high-speed blending actions, allowing various components to be rapidly and evenly mixed. This makes the machine an ideal production equipment for high-end cosmetic powder semi-finished products such as compact powder, blush, and eyeshadow.

3. The machine is equipped with an automatic oil-spraying system. The mist-style spraying enables the powder and oil to mix more thoroughly and evenly.

4. A circulating water cooling system prevents heat buildup during high-speed mixing, ensuring temperature control throughout the process.

5. Powder discharge is achieved via a pneumatic cylinder-controlled lid opening, making the operation simple and convenient.

6. The entire machine is constructed from SUS304 stainless steel, ensuring durability and hygiene compliance.

2. It features two mixing motors that operate from different angles—one from the bottom and one from the side of the mixing barrel. These motors perform crushing, shearing, and high-speed blending actions, allowing various components to be rapidly and evenly mixed. This makes the machine an ideal production equipment for high-end cosmetic powder semi-finished products such as compact powder, blush, and eyeshadow.

3. The machine is equipped with an automatic oil-spraying system. The mist-style spraying enables the powder and oil to mix more thoroughly and evenly.

4. A circulating water cooling system prevents heat buildup during high-speed mixing, ensuring temperature control throughout the process.

5. Powder discharge is achieved via a pneumatic cylinder-controlled lid opening, making the operation simple and convenient.

6. The entire machine is constructed from SUS304 stainless steel, ensuring durability and hygiene compliance.

แกลเลอรีรูปภาพ