เครื่องซีลก้นหลอด

รหัสสินค้า: HX-005

Semi-Automatic Monodose Strip Tube Filling and Sealing Machine

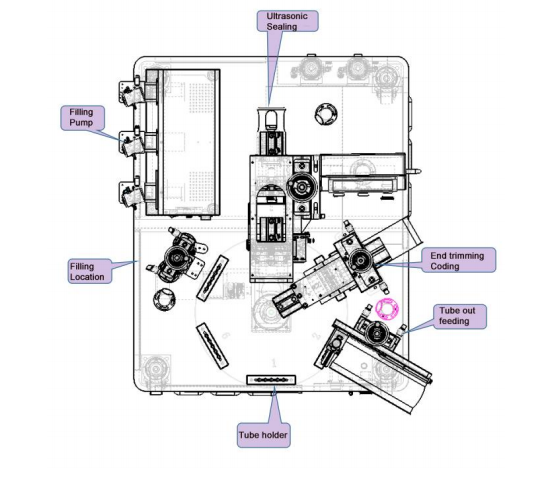

Ultrasonic Sealing

| Model | 005H |

| Frequency | 20KHz |

| Power | 2.6KW |

| Power Supply | AC220V 1PH 50/60hz |

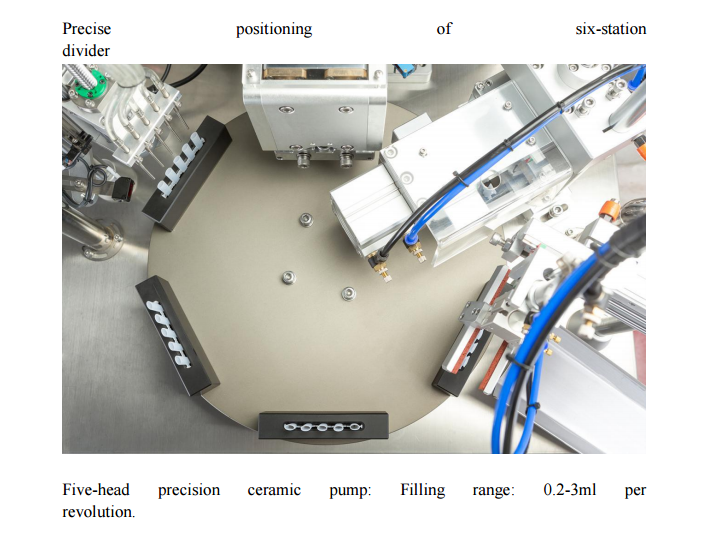

| Filling Volume | 0.2-3ml/rev |

| Filling Accuracy | ±0.05g |

| Productivity | 13-15strips/min |

| Radius of Sealing | 50-135mm |

| Height of Sealing | 50-150mm |

| Air Pressure | 0.6MPa |

| Dimension (L*W*H) | 1300*1300*1950mm |

| Weight | 350Kgs |

Main Parts Details

| Ultrasonic system | Automatic frequency tracing |

| Benchmarking electric eye | Panasonic, Japan |

| PLC | Mitsubishi, Japan |

| Electric relay | Omron, Japan |

| Touch Panel | WEINVIEW,China Taiwan |

| Inductive switch | SICK, Germany |

| Air cylinder | AirTAC,China Taiwan |

| Solenoid valve | AirTAC,China Taiwan |

| Motor | zhongdamotor CN |

| Partitioner | JOUDER,China Taiwan |

รายละเอียดสินค้า

Notes

1. The machine is powered by 220V AC voltage, and the power socket must be

grounded according to the third method of national standard. Don’t pull over the

power cord to prevent it torn.

2. Please pay attention to check and clean the machine before working, and always

add lubricating oil to the sliding parts to ensure the service life of the sliding parts or

it may cause unnecessary accidental damage.

3. The <Alarm Information> screen is mainly used to display the fault points in the

machine work. When an alarm occurs in the machine, the technician can quickly

troubleshoot according to the content prompted in the (alarm information).

4. When the machine has a fault alarm during the operation, please press the

emergency stop switch first to stop the machine. After the fault is resolved, reset the

emergency stop button, and then touch the fault reset button in the screen, the

machine will automatically reset. (The fault reset button is invalid when emergency

stop does not reset).

5. After the machine is reset, make sure that all parts of the machine are normal before

proceeding to the next step (otherwise the machine will make mistakes).

6. There is a 220V voltage inside the electric control box, and non-professionals

cannot open it to avoid accidental electric shock.

7. Do not place it in an environment which has great changes in humidity, or it may

cause condensation inside the device, resulting in damage to the device.

8. When adjusting the speed of each cylinder, it should not be too fast in order to

avoid that the impact is too large to damage the products and equipment parts (it is

better to adjust the speed as fast as possible without the impact sound, but it should be

carried out according to the actual situation).

9. Turn off the power supply and air source when the machine is under maintain or

repairing special faults to prevent accidental injury to the person, such as electric

shock and pinching.

10. Before going to get off work and after work every day, please clean up the

machine to ensure that the machine is clean and free of debris.

11. Regularly (every 10 days) check the lubrication of each sliding part of the

machine. If you find that the lubricating oil is not enough, please add lubricating oil in

time to ensure the normal operation and service life of the machine.

12. Regularly (every week) check whether the screws in the frequently moving parts

are loose. If they are loose, please tighten them in time

1. The machine is powered by 220V AC voltage, and the power socket must be

grounded according to the third method of national standard. Don’t pull over the

power cord to prevent it torn.

2. Please pay attention to check and clean the machine before working, and always

add lubricating oil to the sliding parts to ensure the service life of the sliding parts or

it may cause unnecessary accidental damage.

3. The <Alarm Information> screen is mainly used to display the fault points in the

machine work. When an alarm occurs in the machine, the technician can quickly

troubleshoot according to the content prompted in the (alarm information).

4. When the machine has a fault alarm during the operation, please press the

emergency stop switch first to stop the machine. After the fault is resolved, reset the

emergency stop button, and then touch the fault reset button in the screen, the

machine will automatically reset. (The fault reset button is invalid when emergency

stop does not reset).

5. After the machine is reset, make sure that all parts of the machine are normal before

proceeding to the next step (otherwise the machine will make mistakes).

6. There is a 220V voltage inside the electric control box, and non-professionals

cannot open it to avoid accidental electric shock.

7. Do not place it in an environment which has great changes in humidity, or it may

cause condensation inside the device, resulting in damage to the device.

8. When adjusting the speed of each cylinder, it should not be too fast in order to

avoid that the impact is too large to damage the products and equipment parts (it is

better to adjust the speed as fast as possible without the impact sound, but it should be

carried out according to the actual situation).

9. Turn off the power supply and air source when the machine is under maintain or

repairing special faults to prevent accidental injury to the person, such as electric

shock and pinching.

10. Before going to get off work and after work every day, please clean up the

machine to ensure that the machine is clean and free of debris.

11. Regularly (every 10 days) check the lubrication of each sliding part of the

machine. If you find that the lubricating oil is not enough, please add lubricating oil in

time to ensure the normal operation and service life of the machine.

12. Regularly (every week) check whether the screws in the frequently moving parts

are loose. If they are loose, please tighten them in time

แกลเลอรีรูปภาพ