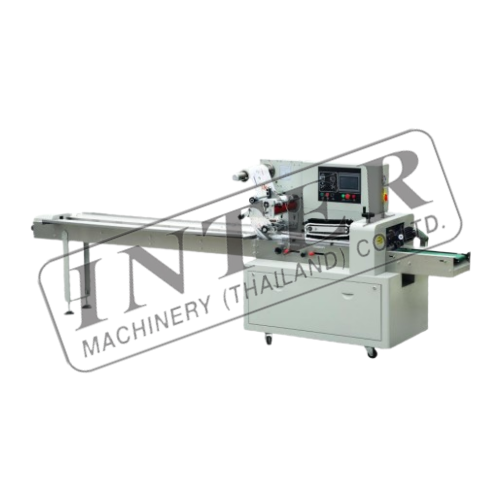

เครื่องบรรจุภัณฑ์แนวนอน

รหัสสินค้า: KD-260A

เครื่องบรรจุแนวนอน รุ่น KD-260A

Technical Parameter

| Model | KD-260A |

| Size of bag (L)(mm) | 60-200mm |

| Size of bag (W)(mm) | 25-100mm |

| Size of bag (H)(mm) | 5-45m |

| Intensity of Sealing | ≥15 |

| Capacity (pack/min) | 25-220 |

| Total Power (kw) | 220V, 50Hz, 2.7Kw |

| Overall weight (kg) | 680KG |

| Dimension (LxWxH)(mm) | 4000mm x 920mm x 1500mm |

รายละเอียดสินค้า

KD-260A Automatic candy packaging machine

Specifications

1.apply more material blocks such as betel,olives,candied fruit,gong date,small electronic components

2.speed:40-220p/min

Application:

apply more material blocks such as betel,olives,candied fruit,gong date, multiple packet soup,solid dispersing materials,small

electronic components of irregular objects.

Featrues:

1.Compact structure, stable function and simple operation.

2.the first third-generation double frequency control,the bag could be set and cut,unnecessary adjust air without changing film color

code tracking one pace reachs the designated position,it's saving time and film.

3.it adopts imported electric appliance,touch manmachine interface,conv-enient parameter setting.

4.self-cheching function, trouble can be rean easily.

5.high sensor photoelectric color chart tracking,make the cutting postion more correctly.

Dependant temperature PID controlling suitable for various materials of packagingmenbrane.

6.Position stop function, no adhesive and no waste of membrane.

7.Clean rotation system, more reliableoperation and more convenient maintenance.

8.All the controlling operates by the software,convenience for function ad-justment and technical up grading

Specifications

1.apply more material blocks such as betel,olives,candied fruit,gong date,small electronic components

2.speed:40-220p/min

Application:

apply more material blocks such as betel,olives,candied fruit,gong date, multiple packet soup,solid dispersing materials,small

electronic components of irregular objects.

Featrues:

1.Compact structure, stable function and simple operation.

2.the first third-generation double frequency control,the bag could be set and cut,unnecessary adjust air without changing film color

code tracking one pace reachs the designated position,it's saving time and film.

3.it adopts imported electric appliance,touch manmachine interface,conv-enient parameter setting.

4.self-cheching function, trouble can be rean easily.

5.high sensor photoelectric color chart tracking,make the cutting postion more correctly.

Dependant temperature PID controlling suitable for various materials of packagingmenbrane.

6.Position stop function, no adhesive and no waste of membrane.

7.Clean rotation system, more reliableoperation and more convenient maintenance.

8.All the controlling operates by the software,convenience for function ad-justment and technical up grading

แกลเลอรีรูปภาพ